In the modern world, businesses of any industry need technologies to improve their potential and productivity. The 5G technology of the fifth generation of mobile networks also plays a key role in boosting competitiveness, as well as helping companies to overcome the challenges of digital disruption.

As the telecom network service provider with the most 5G frequencies, AIS has taken up this important role to help Thai industries improve their potential.

AIS has worked with business allies to create an ecosystem for developing and making use of the 5G technology, according to the company’s chief enterprise business officer Tanapong Ittisakulchai.

The latest collaboration is between AIS Business and the Thai Automation and Robotics Association (TARA), involving the integration of 5G technology and automation and robotics for industrial work, he said.

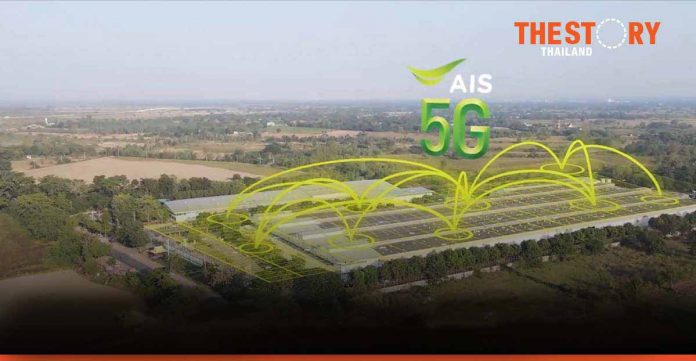

AIS offers the 5G Private Network digital infrastructure service for Yawata (Thailand) Co Ltd factories to support the smart manufacturing solution. In the meantime, TARA encourages Thai entrepreneurs to upgrade their automation and robotics systems and get ready for the 4.0 industrial solution.

The 5G Private Network platform is perfect for use in industrial factories. It has the network slicing capability for better management of available resources, which is ideal for applications with special requirements such as speed and low latency.

The private network is designed for confidential data connections, even through a wireless network, allowing flexibility, high security, and low latency.

Lertvilai and Sons Co Ltd, which provides automation and robotics solutions for industrial manufacturing, helps with developing solutions for actual usage at a Yawata (Thailand) Co Ltd factory on AIS’s 5G network.

“It’s a collaboration to support Thai entrepreneurs in developing smart manufacturing solutions on the 5G network to upgrade Thailand’s digital economy and 4.0 industries,” Tanapong said.

Yawata has started adopting automation and robotics for its production system in a 25,000-square-metre area at its electrode manufacturing plant in Nakhon Ratchasima province, said TARA president Prapin Abhinorasaeth, who is also managing director of Yawata (Thailand). He added that the next plan is to expand collaboration with AIS to other TARA members.

The association’s members are companies involved in the industries relating to automation and robotics, which is one of the 10 new S-curve industries comprising technology developers and makers on the supply side and tech users on the demand side. Under the collaboration with AIS, the association brings together Lertvilai and Sons as the producer and Yawata (Thailand) as the user for a cooperation that has AIS as an important tech ally.

Yawata is Thailand’s major manufacturer of electrodes with the annual production capacity of 180,000 tons. The company, established 48 years ago, has 290 employees and exports to 25 countries. Its electrodes were used in the construction of Bangkok’s Suvarnabhumi International Airport and Rama IX Bridge, among other projects.

The company has adopted technologies to help improve the efficiency, cut costs, and reduce the risk of factory accidents. In upgrading its machinery with 5G technology, Yawata is eligible for three years’ exemption of corporate tax for 100 per cent of the upgrade cost, in accordance with the Board of Investment incentive measures.

The factory’s Information Technology (IT) and Operational Technology (OT) systems are connected through cloud computing. Robots are used in clutching electrodes and moving objects inside the factory. 5G connections at the speed of almost 1 Gbps and the frequency of 2.6 GHz allow data links within the factory as well as with the outside world.

“Robots can move boxes weighing 20 kilograms within 11 seconds, which is faster and more efficient than before. Also, our factory workers gain better quality of life, as they no longer have to carry heavy loads,” Prapin said.

Lertvilai and Sons is a leading producer of industrial robotic automation systems, according to Dr Kunlachat Seniwong Na Ayutthaya, the company’s manager of Robotics and Automation Division. Its products include applications for vision-guided robots, autonomous mobile robots (AMRs), and software for industrial internet of things (IIoT).

The company also serves as a robot training center while providing solutions for warehouse and human resources management. The OT and IT systems are seamlessly connected through the OPC UA protocol run on a 5G private network, which is highly secure.

In the past, communications within the factory area were limited, as they had to rely on WiFi signals, but AIS 5G has got rid of that restriction, allowing the automated systems to work steadily.

Through collaboration with AIS and Yawata, Lertvilai and Sons’ research led to the development of AMRs to replace man-operated forklifts in the production line. The robots move freely within the factory area with no need for guiding lines like in older systems. This has led to increased productivity, higher safety, and better quality of life for employees.

Yawata’s electrode factory has a complex production process that also involves moving raw materials. With the AMR system, the plant is getting closer to the goal of becoming a “smart” factory.

“The Smart Factory solutions have many components, including robotics, AMR and PLC of the IIoT system. It requires connections through OT, IT and cloud in the “everything connected” format,” Kunlachat said.

“The goal is to make the Thai industrial sector recognize the significance of technology in boosting the work potential,” he added.

His company is expanding its collaboration to cover other industrial operators among the association’s members, based on the successful model with Lertvilai and AIS. The alliance between Thai-owned businesses has resulted in not only increased productivity, but also sustainability for the companies involved.

Tanapong also said that AIS is well prepared to usher the Thai industrial sector into the world of 5G industrial solutions that can help different industries drive their changes through technology.

“The collaboration with our allies in developing solutions for industrial plants clearly shows that they work. We believe this collaboration will help improve the ecosystem for Thai operators with increased potential and competitiveness,” he concluded.