Entrepreneurs tend to give up after their businesses suffer big losses. But Wanchai Wongsaeng-anan decided to quit his previous business when it was growing prosperously and making over Bt300 million in annual revenues.

His decisive move came after he realized that his leather tanning business was partly responsible for the slaughter of many animals. This resulted from his serious practice of Buddhism and advice from a monk that he respects.

At that time, his old business became well established after nine years of existence. It had more than 150 employees and its customers included leading brands of premium leather products, such as Coach, Lacoste, Ecco, and Fitflop.

- KBank Private Banking and Lombard Odier recommend seven investment strategies

- DentiiScan: the start of something big in Thai research and development

Wanchai is now the managing director of Result Plus Co Ltd, which owns the brand WashTech (Thailand) providing sterile laundry services for hospitals.

He told The Story Thailand that although his business was not directly responsible for killing the cattle whose hides were used in his tanning factory, he felt that his happiness constantly diminished as he continued doing the business that went against his religious belief.

That was over six years ago, when he was in his late 40s — too early for retirement.

After quitting his old business, the entrepreneur spent about a year studying potential ventures that would meet his ideal of helping others rather than harming anyone.

Start of sterile laundry business

Wanchai revealed that the idea of starting an industrial-scale laundry business came after his meeting with an executive of a private hospital. That was when he learned about high demand from hospitals for completely germ-free laundry, as hospitals have many dirty clothes each day including bed sheets, patient garments, personnel clothing, towels, and dirty clothes from operating rooms.

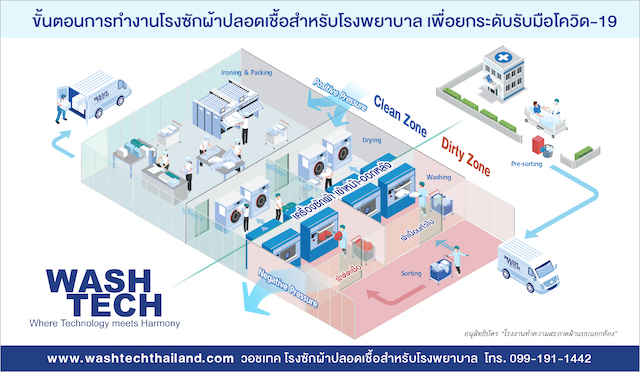

He began studying the laundry business seriously, flying to Japan so that he could visit one of the world’s most advanced laundry factories. He discovered that the laundry process would not be completely germ-free if the dirty clothes could contaminate the freshly laundered clothes somewhere in the system.

Wanchai explained that washing machines used in Thailand’s laundry services mostly are front-loaded, allowing the dirty clothes to be loaded and the laundered clothes to be unloaded through the same door.

“This way, the clean clothes could get contaminated from the dirty clothes, through people, containers or the environment. So, we look for washing machines that can really ensure a germ-free system. They have two doors — one in front for loading and the other at the back for unloading,” he said.

His laundering system is designed to flow one-way and the clean clothes never go against the traffic. The “one-way flow” design is the key to ensure uncontaminated laundry.

Wanchai claims this design, featuring an infection control system, is a first for any laundry business in Thailand. He was inspired by the sterilization room in hospital.

With foreseeable high demand, the entrepreneur looked for a land plot suitable for his new business. It must be located in a zone allowable for an industrial factory and not too far from Bangkok for easy transportation to the central business district.

Eventually, the factory is built on a land plot measuring 4 rai (about 2,000 square metres) in Pathum Thani province’s Lam Lookka district with an investment of Bt100 million.

Like others, Result Plus’ laundry factory has three main sections — for washing, drying, and ironing plus folding. The difference is that the washing section has a large air ventilator to create negative pressure inside the room, preventing germs from traveling airborne to other areas of the factory, particularly the drying and ironing sections.

“Workers in the dirty clothes zone cannot get into the clean clothes zone so that they can’t contaminate the laundered clothes. Also, workers from the clean clothes area are not allowed to enter the dirty clothes zone. The two zones are completely separated, in terms of area, workers and air,” Wanchai said.

He explained that while air is suctioned out of the dirty clothes zone, it is pumped into the adjacent clean clothes zone to create positive pressure. In case of leak, air always flows from the room with positive pressure into the one with negative pressure — that means, from the clean area into the dirty zone.

This guarantees that laundered clothes from Result Plus are germs-free, comparable to sterilized clothes used in any hospital’s operating room, its managing director says.

After more than five years in business, the laundry factory is now capable of dealing with 30 tonnes (90,000 pieces) of clothes a day, up from 10 tonnes (30,000 pieces) in the first phase of its operation.

Its main customers are hospitals, the factory hires more than 170 employees as the business is labour intensive.

Wanchai said that the factory is designed for hygiene, safety and sanitization, with good ventilation and simple quality control. Proper air ventilation inside the factory ensures a happy and comfortable working environment for the workers, he added.

Covid-19 changes views on laundry hygiene

Before washing and drying, clothes of different types, contaminated garments, as well as whites and colours are separated. This is because they require different treatment. During the laundering process, clothes are examined to ensure they are clean and determine if further washing is required.

“Our quality control is acceptable to the customers. The factory removes clothes that are not suitable for further use. This helps prevent hassle for hospitals. We act as a support team that is strong and caring,” Wanchai said.

Having served as a support team to the public health personnel for years, Result Plus could easily win their trust for laundering dirty clothes from hospitals when Covid-19 struck Thailand.

The duty lets Wanchai learn about innovations like the water soluble laundry bag, which helps workers to avoid direct contact with dirty clothes from Covid-19 wards. The innovative laundry bags are sponsored by Chevron and the Ariyawararom Foundation.

The entire laundry process takes no longer than 24 hours, allowing Result Plus to serve hospitals all year round. Small hospitals have one delivery a day while larger ones have up to three deliveries.

Before the Covid-19 pandemic, Result Plus’ laundry factory served 18 private and government hospitals in line with Joint Commission International’s accreditation standard that hospitals have to meet, particularly those that cater to foreign customers.

Local outbreaks of the coronavirus led to a decrease in daily volumes of dirty clothes. But Result Plus saw demand from field hospitals although the costs remained high due to the use of personal protective equipment (PPE) and the need for sanitation system to ensure safety for laundry workers.

Covid-19 has completely changed the views of hospitals and their senior executives about hygiene and sterilization. Recognizing Result Plus’ laundry system, many hospitals commissioned the company to design their systems based on its patented prototype, including Thammasat University Hospital.

Strong commitment, never-ending development

Result Plus remains firmly committed to maintaining sterilization and continued development to improve its efficiency and capability in preparation for social changes and more emerging infectious diseases in the future.

The commitments certainly result in higher operating costs than general laundry businesses. However, for Wanchai, high quality and trust from customers cannot be compromised. Urban hospitals with limited space are increasingly outsourcing to quality laundry services like Result Plus, he said.

As its current factory is nearing the maximum capacity, Result Plus has a plan for expansion with more imported machines, according to Wanchai. The expansion plan can be implemented after the pandemic is over.

Also, there is a plan for expanding the services beyond laundry. New services in the pipeline include collecting dirty clothes from different hospital departments and delivering clean clothes to them. Another planned service involves procuring new quality clothes for hospitals whenever their old clothes need to be replaced.

Result Plus aims to serve as a stronghold in Thailand’s battle against pandemics and help to strengthen the country’s status as a regional medical hub.

“With strong forwards, we also need a strong support team in the back to get a good result. We are proud to have upgraded laundry services for hospitals,” Wanchai said.